Industrial design students from ÉCAL University of Art and Design in Lausanne, Switzerland, created a range of grow-your-own sponge furniture designed to reduce the environmental impact of the furniture industry through the use of shape-memory materials.

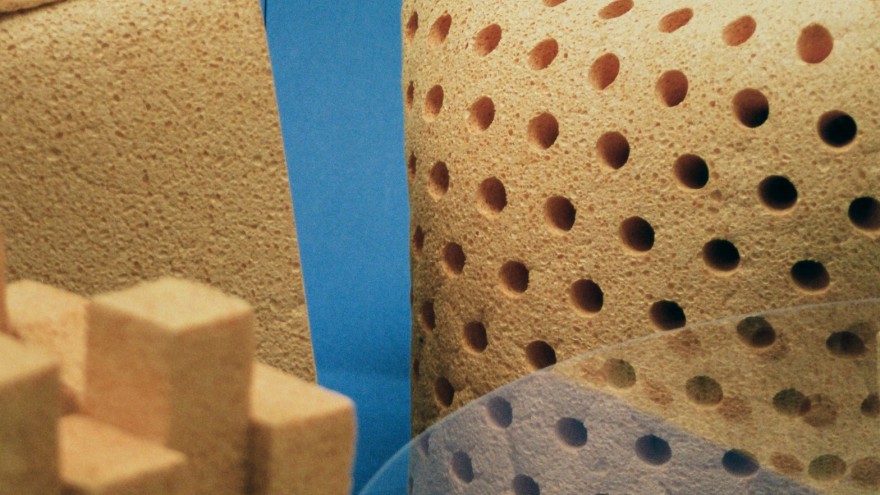

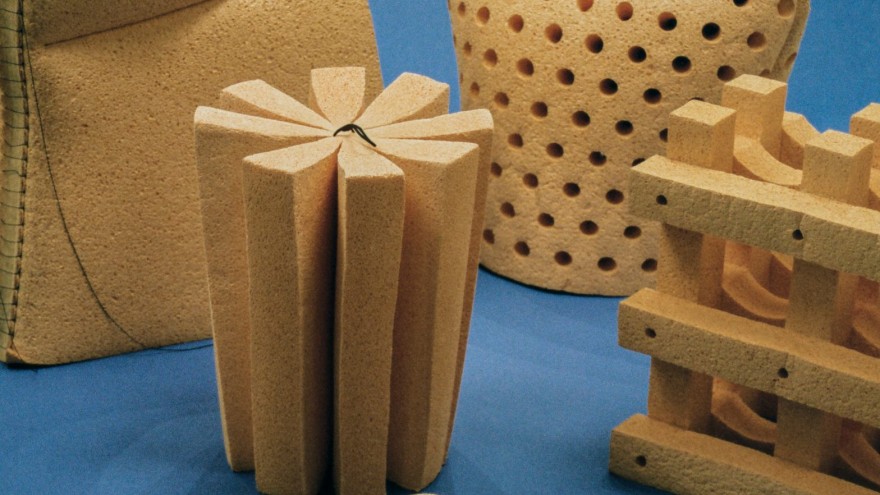

Called UPS, which stands for ‘Under Pressure Solutions’, the experimental furniture is made from cellulose sponge, a biodegradable material made of wood residues, that expands from a dry sponge into a full-size piece of furniture.

Unveiled at Milan Design Week, UPS reimagines a lightweight furniture system that can be shipped across the globe in a compressed form and transformed into full-size furniture without any mechanical assembly needed. Once wrung out, the sponge is left to dry and harden, creating sturdy, self-supporting furniture that can carry the weight of a person and outperform conventional plastic foam in terms of durability, according to the researchers.

‘In a context of permanent environmental and technological mutations, combined with the growing importance of online commerce, industrial design has to consider a new range of climatic, technical and aesthetic challenges,’ explained the designers. ‘This attempt explores a possible solution to reducing the furniture industry’s transportation and production impacts. Thinking of objects occupying as little space as possible for a time, allowing flat-packing, is of obvious interest in this regard.’

Camille Blin, Christophe Guberan, Anthony Guex, Chris Kabel and Julie Richoz were initially inspired by an iconic chair designed in 1969 by the late italian designer Gaetano Pesce: the UP5 chair. Made of polyurethane foam, the chair would expand by itself when unpacked.

After a meticulous process of selecting materials, the team opted for cellulose sponge. Made from wood residues, this material has remarkable properties: it is biodegradable and expands 10 times its initial size on contact with moisture. The development of prototypes, based on numerous experiments carried out beforehand, highlighted the material’s versatility and strength, demonstrating its potential as a sustainable alternative for furniture production.

‘Moreover, the project is also an aesthetic endeavour, exploring new design typologies and solutions in furniture design, generated by a specific set of constraints, such as compressibility, durability, as well as functionality,’ said the designers.

READ MORE